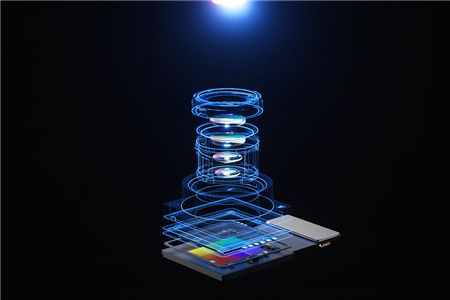

Full-Stack Full-Scenario Robotic Vision System Solution

Sunny OIT creates a comprehensive 2D & 3D vision solution that covers a wide range of scenarios, focusing on deep applications in the fields of AR&VR, robotics, and AIoT.

Technology

Sunny Optical

Hardware Development

Driver Development

Applied Algorithm

Visual Algorithm

Mass Production Technology

Hardware Development

Sunny OIT boasts a visual sensor and hardware development center that spans various technical domains, including electronic design, mechanical design, industrial design (ID design), hardware design, and optical design. This center has achieved efficient miniaturization packaging for camera modules, ensuring exceptional product performance within compact architectures, and delivers high-performance, high-reliability robotic vision solutions to clients.

Driver Development

Sunny OIT has established a multi-modal sensor technology platform through systematic optimization of both hardware and software, enabling seamless integration between visual modules and other peripherals. Additionally, in-depth optimizations have been conducted on the ISP and IVE, significantly enhancing image processing speed and quality. Leveraging the hardware computing power of the embedded platform's NPU, ARM, GPU, and DSP, fundamental optimizations of image processing algorithms have been implemented. By designing a lightweight network architecture and employing quantization training techniques, efficient visual perception on the edge side has been achieved. Furthermore, by optimizing the underlying software for heterogeneous multi-core systems and data transmission protocols, low-latency real-time responses have been realized. Currently, the company's related products have been mass-produced and are being applied in multiple client projects.

Applied Algorithm

Sunny OIT constructs a full-stack, full-scenario robotic vision solution that spans from consumer-grade to commercial-grade and professional-grade applications. The technology stack includes SLAM, deployment mapping, autonomous positioning, obstacle avoidance, delivery, and patrolling, among others, making it suitable for environments of varying complexity. It also encompasses biometric recognition technologies such as facial recognition, palm vein recognition, and palm print recognition, as well as applications like 3D reconstruction, gesture recognition, human pose recognition, eye tracking, 6DoF, and 3D measurement. This ensures comprehensive coverage from simple household assistance and commercial use to professional-grade visual analysis in precision manufacturing, fully meeting customer demands across diverse scenarios.

Visual Algorithm

Sunny OIT specializes in the research and development of robotic vision modules and components, possessing a comprehensive spectrum of visual technologies. This includes 2D visual technologies such as RGB, IR, and Mono, as well as 3D visual technologies like iToF, dToF, structured light, and binocular systems. The company has established a professional visual perception and multi-modal algorithm R&D center, focusing on the development of underlying visual algorithms, including automatic annotation, distributed training, quantization training, data augmentation, contour feature recognition, and data fusion. Additionally, through the application of 3D-CP hardcore processing technology, 2D/3D ISP processing technology, and multi-sensor calibration techniques, Sunny OIT provides efficient and accurate visual processing solutions.

Mass Production Technology

Sunny OIT boasts advanced mass production technology and exceptional manufacturing capabilities, with a smart manufacturing base for optoelectronic modules, components, and complete machines that exceeds 40,000 square meters. This includes the COB and AA class 100 clean rooms, the component assembly class 1,000 clean rooms, the SMT class 10,000 clean rooms, and the complete machine assembly class 100,000 clean rooms, ensuring high cleanliness and quality during the production process. A comprehensive quality assurance system has been established, covering every step from incoming materials, manufacturing processes, to shipment. Through precision packaging, universal AA, proprietary algorithm calibration, and Automated Optical Inspection technologies, we achieve an efficient and accurate production process, providing customers with stable and reliable visual module products, as well as comprehensive OEM services to meet the customized needs of various clients.